3D printing has made great progress in recent years and is now used in many areas – from private hobby projects to industrial production. But how exactly does 3D printing work and what areas of application are there today? In this article, we provide an easy-to-understand overview.

How does 3D printing work?

In 3D printing, a three-dimensional object is built up layer by layer. In contrast to conventional manufacturing methods in which material is removed (e.g. milling or drilling), 3D printing is based on the additive principle: the material is applied layer by layer until the desired object is created.

There are various 3D printing processes, the best known of which are

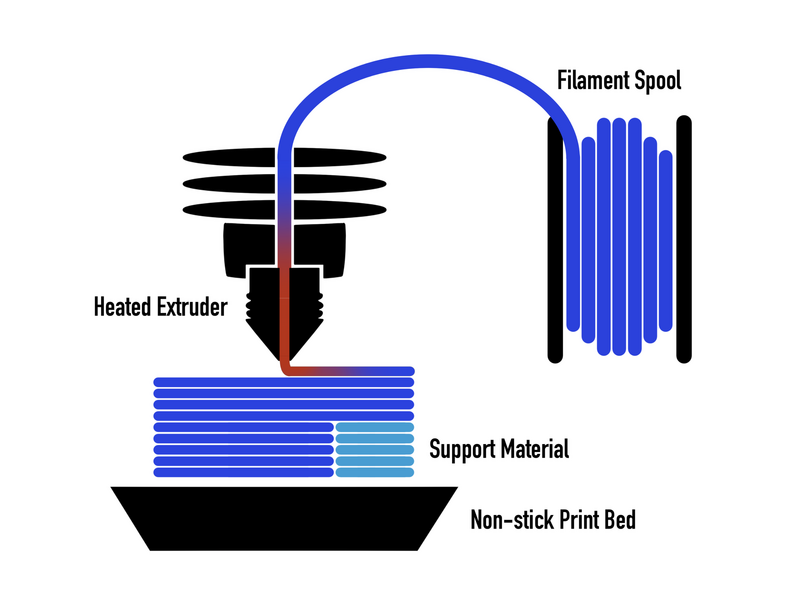

- FDM (Fused Deposition Modelling): This is the most widely used process for private use. A plastic filament (e.g. PLA, PETG or ABS) is heated and applied to the printing plate through a fine nozzle. The model is created layer by layer.

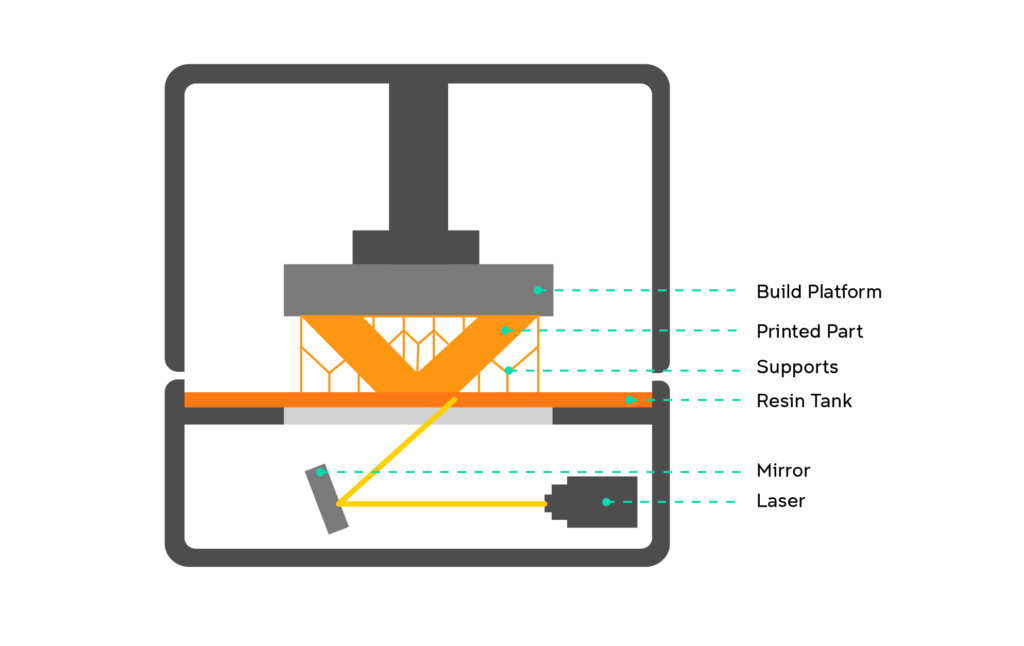

- SLA (stereolithography): Here, a liquid resin is cured with UV light. This process enables particularly fine details and is often used for high-precision applications, e.g. in dentistry or jewellery production.

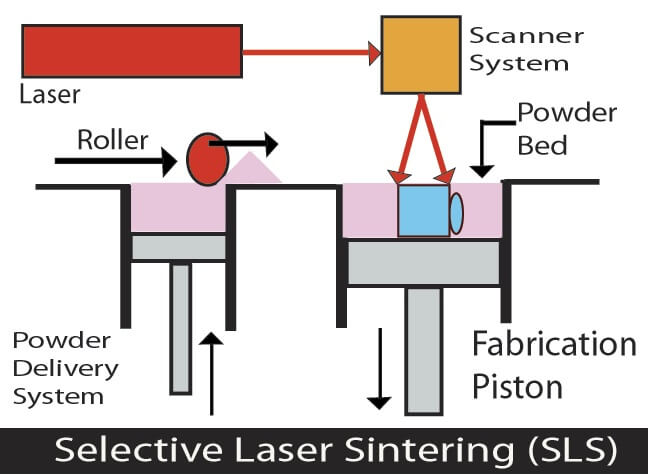

- SLS (selective laser sintering): Fine powder (often nylon or metal) is used here instead of plastic or resin. A laser melts the particles together at the desired points. This technique is mainly used in industry for robust components.

There are also many other methods, such as binder jetting for metal parts or HP’s multi-jet fusion process, which is used in mass production.

Applications in the private sector

Many people now use 3D printers at home. There are many reasons for this:

- Printing spare parts: Who hasn’t experienced this? A small plastic part of an appliance breaks and the manufacturer doesn’t offer a replacement. With a 3D printer, you can easily reprint such parts yourself.

- Personalised objects: Whether it’s a mobile phone stand, cable holder or key ring – a 3D printer can be used to make individual and practical items.

- Model making & cosplay: Many hobbyists use 3D printing to produce detailed models for tabletop games, model trains or costume parts for cosplay.

- Education & learning: 3D printing is also a great tool for schools and educational institutions to teach technical knowledge in a practical way.

Use in industry and science

Companies are also increasingly turning to 3D printing. Here are some important areas of application:

- Prototyping: a product can be quickly tested as a 3D-printed model before series production. This saves time and costs in development.

- Medicine: From individually adapted dental implants to customised prostheses – 3D printing is revolutionising medicine. Organs made from bio-ink are also already being developed.

- Aerospace: Companies such as NASA and SpaceX are using 3D printing to produce lightweight, stable components for rockets and satellites.

- Construction: In some countries, houses are already being built using 3D printers – faster, cheaper and more sustainable than with traditional methods.

- Automotive industry: Manufacturers such as BMW and Tesla use 3D printing for special parts, prototypes and even complete car body parts.

My personal journey into 3D printing

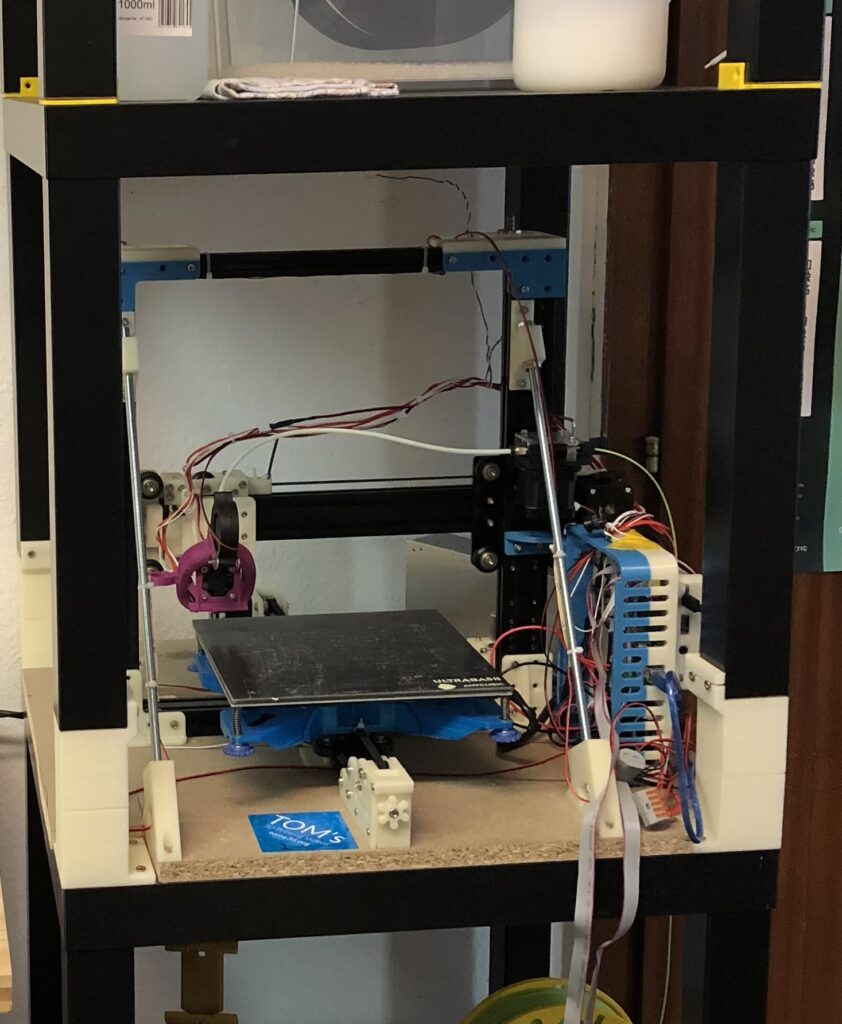

My interest in 3D printing began in 2016 when I first heard about this fascinating technology. The possibility of producing my own components and objects immediately piqued my curiosity. In 2017, I finally decided to buy my first 3D printer. The first projects mainly consisted of small spare parts, such as gears for toys or practical boxes for organising screws and tools.

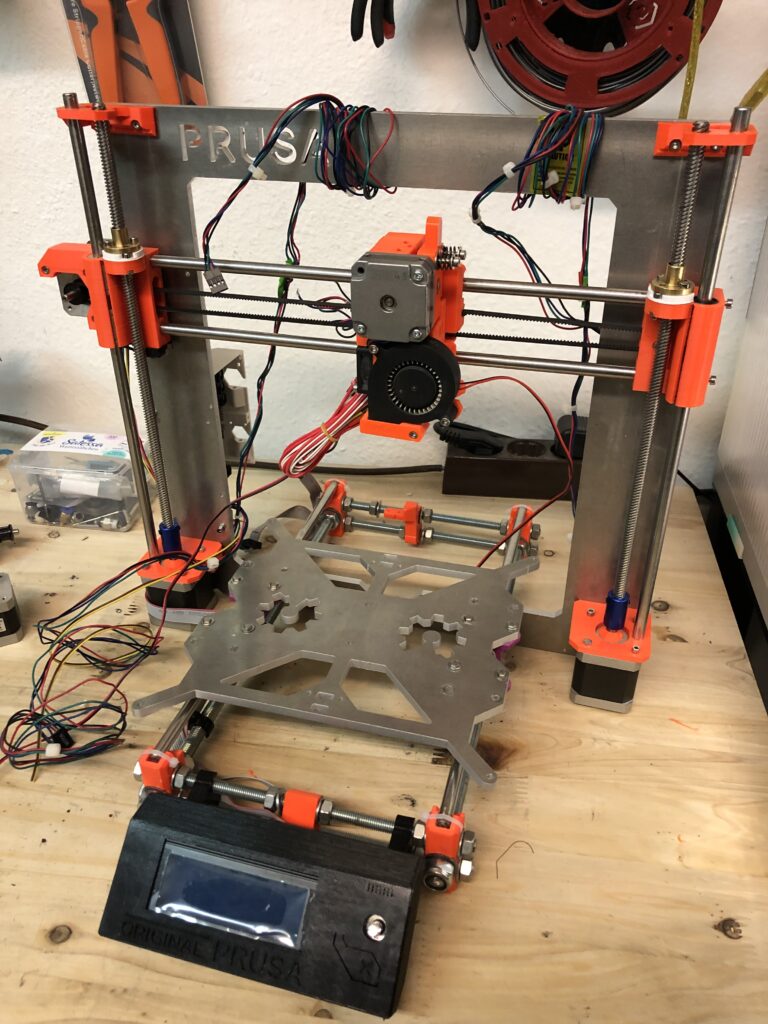

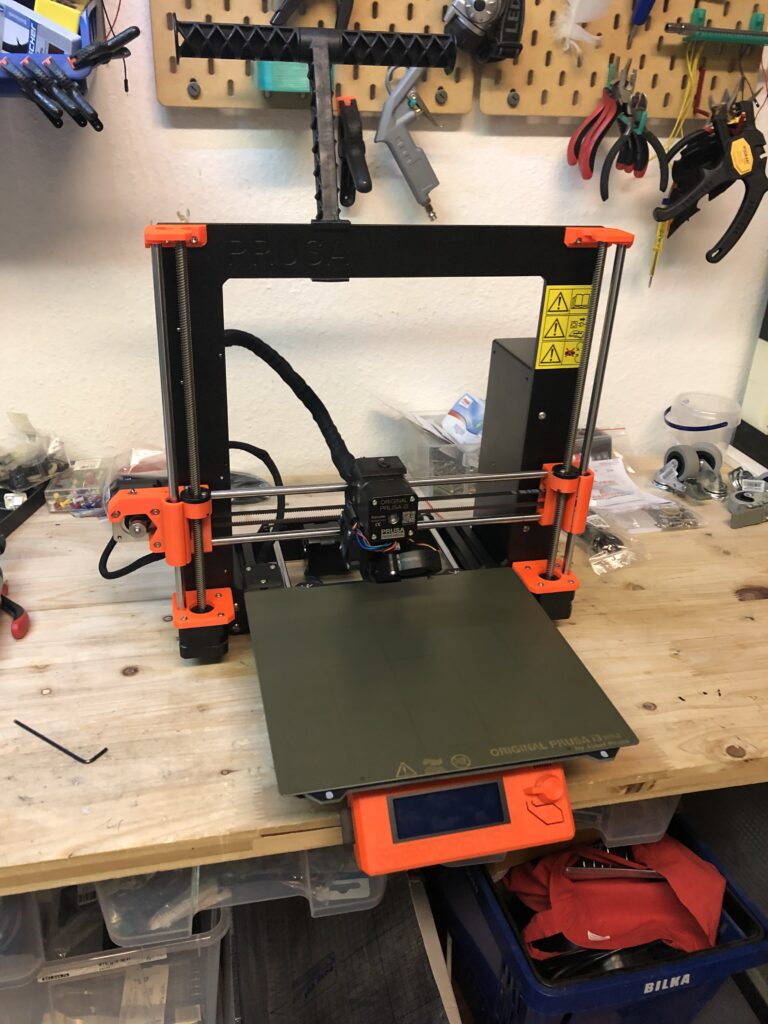

Over time, my prints became more and more complex. I started designing special inserts for board games to better sort game materials and experimented with modelling components. In 2019, I invested in a modern printer – the Prusa MK3sPlus – which allowed me to make even more precise and reliable prints.

Today, I use 3D printing for a variety of applications: from functional kitchen gadgets and customised organisers to special spare parts that would otherwise be difficult to obtain. I’m particularly excited by the opportunity to find customised solutions to everyday problems and be creative at the same time.

Conclusion

3D printing is a revolutionary technology that is finding its way into more and more areas. While it offers many creative possibilities for private individuals, it is also driving innovation in industry. The continuous development of the technology could make even more exciting applications possible in the future – from 3D-printed food to the printing of organs for transplants.